Efforts to save energy

As part of our business activities, our company (Antom Co., Ltd.) is actively working to save energy by downsizing our equipment.

Reflow ovens and heating furnaces are equipment that uses heat, so their power consumption is higher than other equipment.

In addition, as the supply of nitrogen has become commonplace due to lead-free solder, many workplaces are worried about the increased running costs due to the use of nitrogen.

Therefore, by thoroughly downsizing the reflow furnaces and heating furnaces that we provide, we have set a theme that we as a company should strive to achieve energy savings, such as reducing power consumption during start-up and significantly reducing nitrogen usage.

Achieving energy savings by significantly reducing nitrogen usage

Regarding nitrogen usage, the nitrogen flow rate required to achieve an oxygen concentration of 200ppm in the furnace can be reduced to 150L/min or less.

Continuous nitrogen usage has a large impact on monthly running costs, so reducing the flow rate of nitrogen used in equipment not only helps the environment through energy savings, but also greatly contributes to cost reductions in factories. Is possible.

Achieving energy savings by strengthening the insulation structure

Some of our reflow ovens and heating furnaces can be set up to a maximum of 350℃, and the upper limit of the temperature setting tends to be higher than that of general reflow ovens and heating furnaces.

Therefore, in order to prevent the equipment’s outer panel temperature from rising too high, we strengthened the insulation structure so that the outer panel temperature remains below 50℃ even when all zones are set to 350℃.

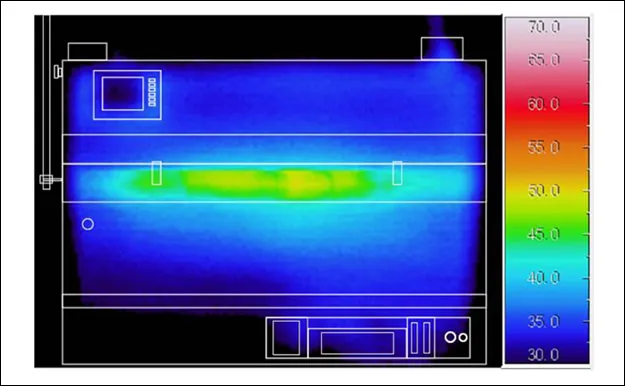

The above thermograph data was measured with the UNI-6116S, the model with the highest temperature setting (350℃) in our lineup, when all zones were set to 350℃.

Even when all zones are set to 350°C, the outer panel temperature can be kept below 50°C, allowing equipment to be used without putting a burden on workers or the air-conditioned environment in the factory.

Achieving energy savings by significantly reducing model changeover (temperature change) time

Generally, when changing the model (temperature change) in a reflow oven or heating furnace, it often takes time to change from a high temperature to a low temperature.

I’ve heard of cases where people try to force the temperature down by opening the hood of the reflow oven or heating furnace fully in order to lower the temperature as quickly as possible.

However, opening the hood while the reflow oven or heating furnace is in operation not only poses a risk of burns, but also puts a heavy burden on the electrical components of the equipment as hot air is sent into the oven all at once. In the worst case scenario, the equipment may malfunction.

Our small reflow ovens and heating furnaces use heating structures that are designed to significantly shorten the time required to change models (change temperatures), so you can save time without running the risks listed above. It is possible to reach the desired temperature setting in hours.

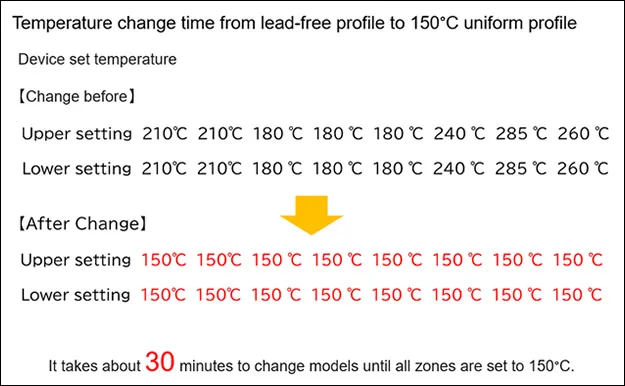

The temperature settings below are for reference purposes only, and are the actual time taken when lowering the temperature uniformly by 150℃ in all zones, based on the temperature settings for the lead-free profile.

The model used for this measurement is the SOL series, which has the longest overall length and the largest number of zones in our lineup, so a smaller model would further reduce the time it takes to change models (temperature changes). You can expect it to be done.

This reduces unnecessary power usage time, allowing for more efficient production.

Click here for detailed information on the SOL series.

We aim to contribute to the realization of decarbonization (carbon neutrality) through energy conservation.

The greater the amount of electricity used (power consumption), the greater the amount of carbon dioxide (CO2) emitted.

Reducing the power consumption of reflow ovens and heating furnaces, which consume particularly large amounts of power among production equipment, can also contribute to the realization of decarbonization (carbon neutrality), so we are a pioneer company in the field of small reflow ovens and small heating furnaces. It is no exaggeration to say that this is our company’s mission.

By promoting the miniaturization of reflow ovens and heating furnaces more than ever before, we aim to contribute to the realization of decarbonization by developing and providing energy-saving equipment that reduces power consumption.

Antom Co., Ltd. has been certified under the Yokohama City SDGs certification system “Y-SDGs”.

On April 10, 2023, Antom Co., Ltd. supported the activities of “Y-SDGs”, the Yokohama City SDGs certification system established by Yokohama City, and its efforts were recognized and certified as a standard.

We will continue to work towards achieving the SDGs (Sustainable Development Goals) through our corporate activities.